Trimmings and other bits.

Repairing the hockey sticks.

Both hockey sticks were not in good condition. One stick had all three studs broken and the other stick two studs broken with the third stud in not to good a condition. I had bought two hockey sticks off Trade Me that were in good condition but didn’t realise that series 2 with the cheese grater grill had different hockey sticks to that of the Morris 1000. So to fix the ones I had, I had to grind the broken studs down to the diecast. Centre punch the middle of the stud. Then I got a 1/8 drill and set the drill press up so the drill would stop before it went right through the hockey stick. Taking it slowly I drilled the stud. Then I got a 5/32 drill and repeated the process. Seeing I was going to try and put a thread into the diecast I thought a corse thread would be better than a fine metric thread. Hence I chose a 3/16 whitworth tap. The first tap was a taper and of course bottomed out after a couple of turns so I ground an other 3/16w tap flat on the bottom and turned it into a plug tap. With this I managed to tap the hole to a depth of about 8mm. With a spring washer behind a short 3/16 whitworth screw, the hockey stick should stay in place no trouble at all.

Stripping the deck to see if it is repairable.

Stripping the deck.

The company that made the back end.

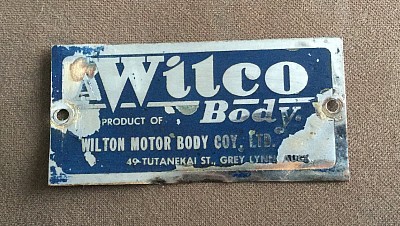

As I said on the main page the deck was made in the Wilton Motor Body Company Ltd. 49 Tutanekai st. grey Lynn Auckland. This firm was around in the 1950’s but this address is now a residential area.